MainProduction

Production

Producing high quality valves requires accuracy in each step of the process, from design to delivery. Detailed planning, precise machining, strict control mechanisms are all structured according to the principles of ISO management.

01

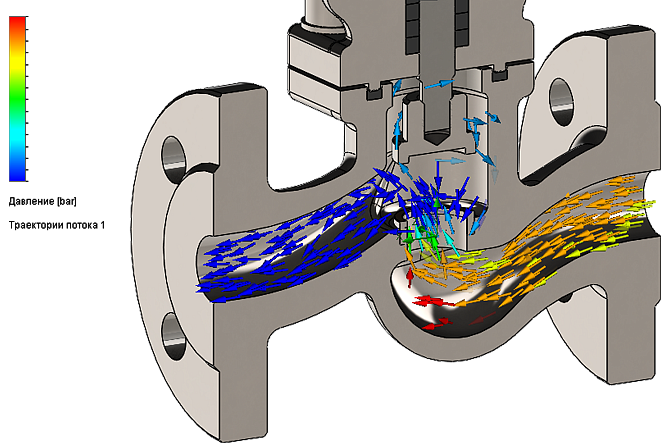

Design

Inhouse design with a high degree of automatization is core to our operative response times. The basic design work is done in 3D. After this, the 3D models are tested for media pressure and risk of cavitation. The last step before serial production is making a sample that is pressure tested at conditions as close as possible to our customer’s.

03

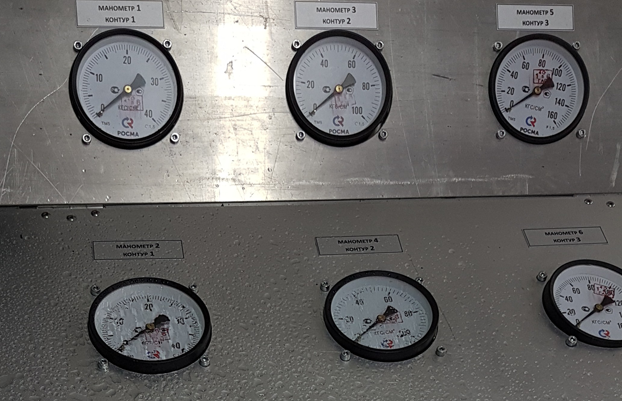

Mechanical works

At the core of our quality lays precise machining on our CNC equipment. We have waterjet cutting, milling and turning, spherical and cylindric grinding. Our skilled machine operators, all with technical education, guarantee a high, stable output level.

04

Assembly

Only parts that have been cleared by our internal quality department are allowed in the assembly area. The assembly work follows a strict procedure, transforming the individual parts into a finished valve.

05

Paint

Paint is applied on clean and well-prepared surfaces to assure the best possible protection of the valve. The choice of paint is made according to our customer’s specific work conditions.

We employ European technologies, machine equipment and management approach in combination with local resources and have extensive experience in developing products for a specific type of production.

For more information, please use